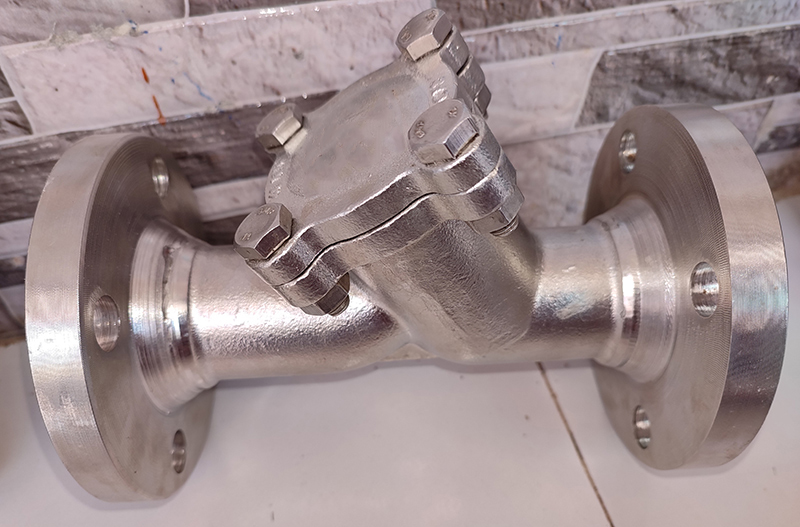

“Y” Strainer or “Y” Strainer Valve is designed to distinct the debris from the pipelines and works as safeguard for the downstream machineries such as pumps, flow meters, steam traps, control valves, sensors and many more mechanical & critical devices.

So, it is the device which is used for filtration, purification, to remove the solid particles from the flowing liquid

The Strainers arrest the debris such as solid waste, corrosion, welding metal in the pipelines. It minimizes shutdown time and repairs.

One should use a correct strainer for the given application. Please contact to the factory for correct installation position. The Strainers are generally used horizontally in the upstream side.

“T” type strainers are generally used in large pipeline size above 50mm. It is mostly come in flange end connection. It is acceptable fabricated in nature as per manufacturer standard. Due to fabricated, the cost of “T” strainers is economical for the large size of pipeline. It can be installed in vertical as well as horizontal pipes. The mesh used inside the “T” strainer are variety standard. The cover of “T” strainer comes with bolted while it is not recommended in other way.

The Basket Strainers handles a lot of fluids for filtration and remove the solid debris from the medium. It is available most of all size and can be customized with the requirements of applications. The baskets are easy to remove and clean from the pipeline.

Upon the specific application requirement, the basket strainers are designed in single cylinder, Duplex strainer or filters, Triplex strainer or filters and multi-cylinder with pleated styles.

There is filter housing, perforated cage-supported filter element, a positive sealing arrangement to prevent any bypass and end link choices inside the filter.

A basket strainer is a closed vessel with cleanable screen element designed to remove and retain debris and solid particles down to 25.4µ (micron meter)diameter from various liquids.

The water entersinto the inlet and it go through the mesh. The solid particles are trapped inside the basket filter screen. After this continuous filtration process the mesh got filled with the debris and filtering process gets slower over time.In the pipeline there is sewage and other foreign elements stuck the hole of the mesh. Thus, the hole going to smaller. Because of thisthe differential pressure arises at inlet to outlet. When the differential pressure exceeds over a fixed value, the differential pressure sensor gives a signal. This signal uses as input signal at the drain of basket strainer. The automated drain valve starts to open and discharge the waste. The differential pressure sensor senses the minimum differential pressure in the line and the drain valve start to close and system works normally. There are several accessories required to accomplish this as casing, several filter components, backwashing device, differential pressure regulator etc…

These strainers are useful in petrochemical processes, potable & wastewater and many process industries such as Power industry, Environmental industry, Food, and chemical industry, etc.