The Ball Float Steam Trap works on the principle of steam density differentials. The floating trap ball is mechanical assembled. Whenever the fluid filled in the chamber, the ball floating, it causes to activate the gate stem and valve allow to drain. If the level of fluid is low, the valve will be closed due to steam push the ball downwards. The steam flow rate is controlled way from the ball float steam trap. Thus, it separates the steam and water mechanically and prevent the steam wastage. The moisture and air always present in the steam line, which have bad effects upon the pipeline. Due to this effect, heating space may be generated. This heating space makes a water film on air pockets and this caused of heat transfer.

A ball float steam trap allows to drain the water which is available in the form of moisture from the steam system without heat escape. It is always installed at the lover level of the ground due to gravity effect for drained. The mechanical arrangement allows the automatic drain of the water from the steam system. The steam with water moisture flow through the chamber and trapped. The density of water is denser than steam so the it falls bottom of the trap. A continuous process of this mechanical effect, the water full in drain chamber. Once the water full in drain chamber, the float activated to drain the filled water. This water drained and returned in the heating system to generate the steam in the system.

A name suggest that Thermostatic Steam Trap is the one specific type of steam trap that works upon the principal of temperature difference. The pressure sensed by steam by thermostatic element and this causes thermostatic steam trap to close.When the non-condensable and condensate gases in the cooling leg back up, the temperature starts dropping and the thermostatic element contacts to open a valve. The quantity of backed-up condensate ahead of the thermostatic steam trap depends on steam pressure, load conditions, and pipe size.

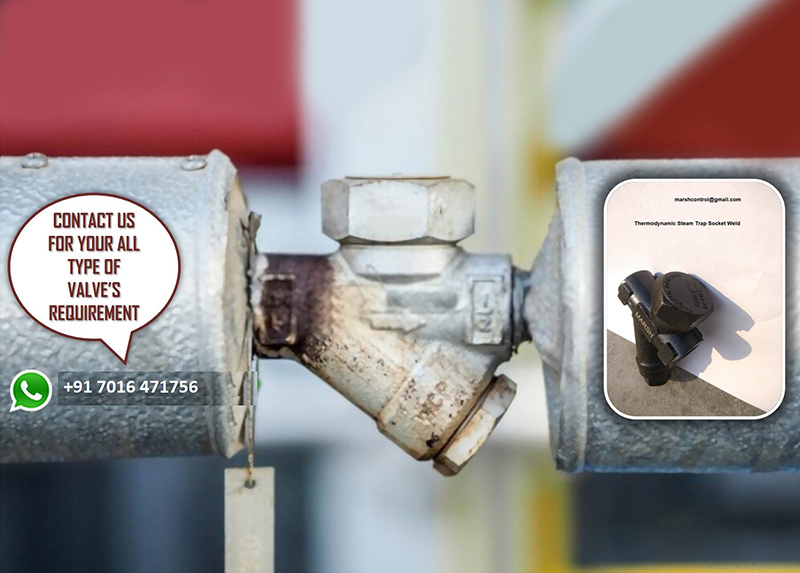

The Thermodynamic Steam Trap is made of one solitary poignant fragment. This fragment is called disc which is made of stainless steel. The steam dynamic principal caused to operate this valve. Thermodynamic steam trap is used for high-pressure steam application. It is small and has not affected by water hammering. It is easy in installation horizontally or vertically as per application demands. Thermodynamic steam trap is a compact in design and adaptable for a comprehensive pressure range. Such characteristics have made thermodynamic steam traps more preferred for steam applications.

The disc type trap opens and closes as per the force changes that take place on a flat disc valve.

The impulse trap, the piston disc movement is used to control flow smoothly.

Inverted Bucket Steam Trap is a mechanical steam trap. It works the upon the principal of density difference. We know the steam has lower density than water. When steam enters into the inverted bucket steam trap, the bucket float closes the drain valve and condensate enters the bucket float open the drain and discharge the water. It is designed to vent carbon dioxide and air continuously at the same steam temperature. There is a linkage mechanism connected to the bucket opens or closes the discharge valve which traps condensate or allows it to escape. It is made of and inverted bucket which is attached to a valve by using a lever mechanism.