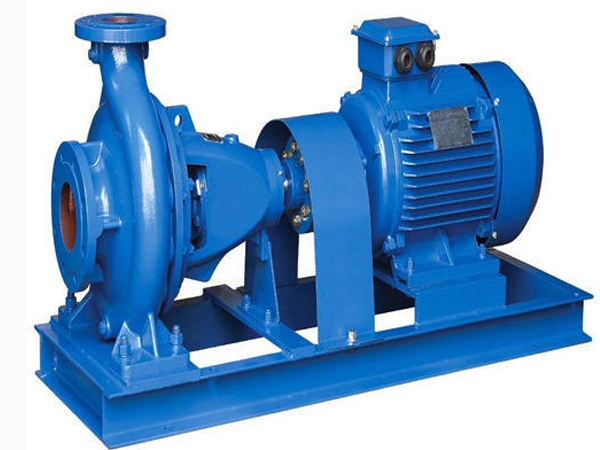

A centrifugal pump is a mechanical device designed to transfer a fluid by means of the transmission of rotational energy from one or more driven rotors, called impellers. Fluid come in the rapidly rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller’s vane tips. The action of the impeller rises the fluid’s velocity and pressure and also guides it towards the pump outlet. The pump casing is specially designed to compress the fluid from the pump inlet, through it into the impeller and then slow and control the fluid before discharge

The impeller is the key section of a centrifugal pump. It consists of a series of curved vanes. These are normally sandwiched between two discs (an enclosed impeller). For fluids with dragged solids, an open or semi-open impeller (backed by a single disc) is preferred.

Fluid pass in the impeller at its axis (the ‘eye’) and exits along the circumference between the vanes. The impeller, on the opposite side to the eye, is connected through a drive shaft to a motor and rotated at high speed (naturally 500-5000rpm). The rotational motion of the impeller accelerates the fluid out through the impeller vanes into the pump casing.

The purpose in both designs is to guide the fluid flow into a controlled discharge at pressure.

In a volute casing, the impeller is offset, effectively creating a curved funnel with an increasing cross-sectional area towards the pump outlet. This design causes the fluid pressure to upsurgein the direction of the outlet.

The same basic principle applies to diffuser designs. In this case, the fluid pressure surges as fluid is expelled between a set of stationary vanes surrounding the impeller. Diffuser designs can be custom-made for specific applications and can therefore be more efficient. Volute cases are better suited to applications involving dragged solids or high viscosity fluids when it is advantageous to avoid the added constrictions of diffuser vanes. The asymmetry of the volute design can result in greater wear on the impeller and drive shaft.

In comparison to the latter, centrifugal pumps are usually specified for higher flows and for pumping lower viscosity liquids, down to 0.1 cP. In some chemical plants, 90% of the pumps in use will be centrifugal pumps. However, there are a number of applications for which positive displacement pumps are preferred.